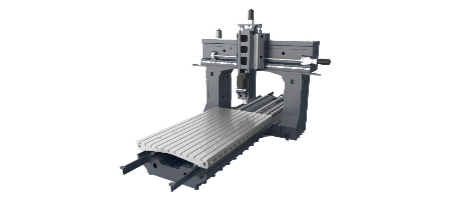

Gantry Machining Center LM3023

Specifications

X-axis travel

3000mm

Y-axis travel

2200(full travel 2700)mm

Z-axis travel

1000mm

Distance from spindle end face to worktable

280-1280mm

Gantry passing height

1400mm

Gantry width

2300mm

Worktable size

3000*2000mm

T-slot quantity/size/spacing

9*28*200

Maximum loading capacity

10000kg

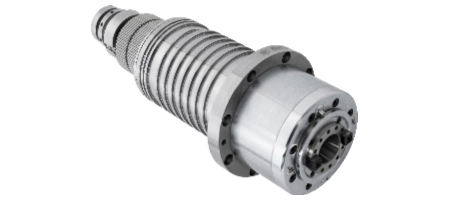

Spindle speed

50-6000rpm

Drive mode

Belt drive

Spindle motor torque (rated/maximum)

143/236Nm

Main motor power

15/18.5kw

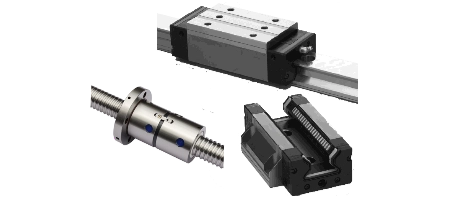

X/Y/Z rapid traverse speed

12/10/10m/min

Cutting feed rate

1-8000mm/min

Counterbalance method

Nitrogen counterbalance

Minimum feed

0.001mm

Tool magazine type

ATC tool magazine (optional)

Shank specification

BT-50

Max tool length

300mm

Machine footprint and height

7830*5200*5370

Machine weight (apx.)

35000kg

CNC system

FANUC 0iMF PLUS

Positioning accuracy(X/Y/Z)

0.018/0.018/0.015mm